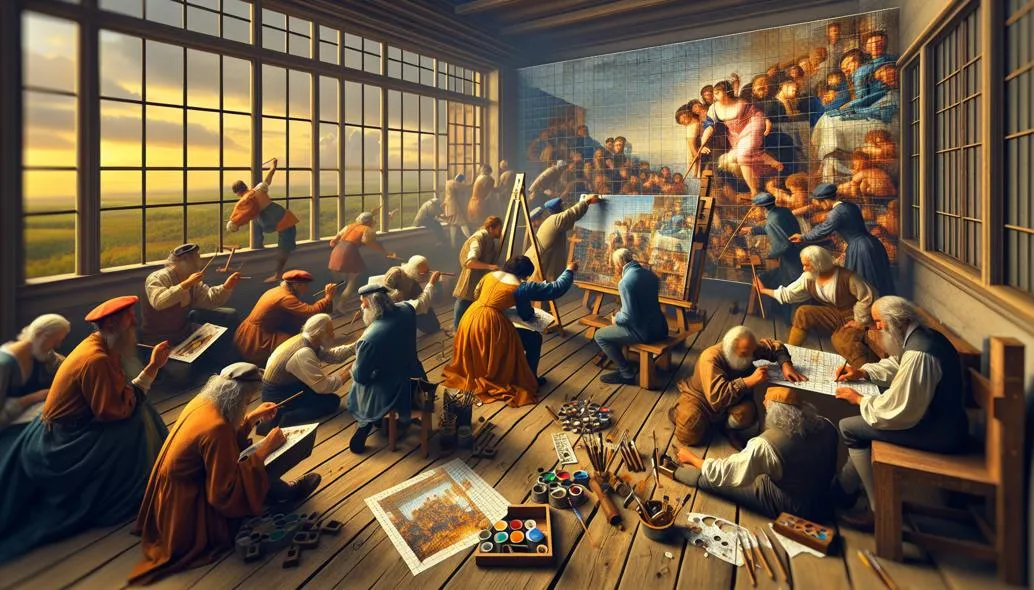

Complex mechanical objects present unique drawing challenges requiring systematic approaches that ensure dimensional accuracy, proper component relationships, and technical precision. Grid methods provide technical artists, engineers, and designers with reliable frameworks for capturing intricate mechanical details while maintaining the proportional relationships essential for professional technical illustration.

How to Use the Grid Method to Draw Complex Mechanical Objects

Professional technical drawing of mechanical objects demands precision that extends beyond artistic representation to encompass engineering accuracy and functional understanding. Grid methods provide systematic approaches for managing the complexity inherent in mechanical subjects, breaking intricate assemblies into manageable segments while preserving critical dimensional relationships and component interdependencies.

The challenge of mechanical drawing lies in translating three-dimensional mechanical complexity onto two-dimensional surfaces while maintaining technical accuracy and visual clarity. Through systematic grid application, artists develop both technical precision and the analytical skills necessary for understanding how mechanical components relate spatially and functionally within complex assemblies.

Understanding Mechanical Drawing Requirements

If you’re drawing mechanical objects, a grid helps you keep alignments and proportions stable while you build clean structure lines. You can create a reference grid with our grid drawing tool.

Technical Precision versus Artistic Expression

Professional mechanical drawing serves dual purposes requiring balanced approaches:

Technical accuracy requirements:

- Dimensional precision: Accurate proportional relationships between components

- Functional representation: Clear indication of mechanical relationships

- Assembly logic: Proper spatial arrangements of interconnected parts

- Material indication: Appropriate representation of different materials and finishes

- Engineering communication: Clear technical communication through visual means

Artistic quality standards:

- Visual clarity: Clean, readable line quality and organization

- Compositional balance: Effective arrangement within drawing format

- Depth and dimensionality: Three-dimensional form representation

- Surface quality indication: Texture, finish, and material characteristics

- Professional presentation: Industry-standard drawing conventions

Types of Mechanical Objects and Grid Applications

Simple mechanical components:

- Individual parts: Gears, brackets, fasteners, simple assemblies

- Single function items: Tools, basic instruments, mechanical elements

- Geometric forms: Cylindrical, rectangular, and angular mechanical shapes

- Surface detail focus: Thread patterns, machined surfaces, cast textures

- Material characteristics: Metal finishes, plastic surfaces, composite materials

Complex mechanical assemblies:

- Multi-component systems: Engines, transmissions, complex machinery

- Interconnected mechanisms: Linkages, gear trains, hydraulic systems

- Cutaway illustrations: Internal component relationships and functions

- Exploded views: Component separation showing assembly relationships

- Cross-sectional views: Internal structure and component arrangements

Specialized Grid Systems for Mechanical Drawing

Engineering-Based Grid Construction

Orthogonal grid systems:

- Primary axes: Horizontal and vertical alignment with mechanical axes

- Engineering scales: Grid dimensions based on standard measurement units

- Component alignment: Grid lines corresponding to major component boundaries

- Assembly reference: Grid serving as measurement reference for component relationships

- Dimensional checking: Grid as verification tool for proportional accuracy

Perspective grid adaptations:

- Isometric grids: 30-degree angle grids for three-dimensional representation

- Two-point perspective: Complex mechanical assemblies in architectural context

- Vanishing point coordination: Multiple perspective systems for complex objects

- Foreshortening accommodation: Accurate representation of depth relationships

- Environmental integration: Mechanical objects within operational contexts

Component-Specific Grid Strategies

Circular and cylindrical components:

- Radial grid systems: Concentric circles with radial divisions

- Elliptical construction: Accurate cylinder representation in perspective

- Threaded surfaces: Specialized grids for screw thread accuracy

- Rotational symmetry: Grid systems accommodating repetitive angular features

- Bearing surfaces: Precise circular form construction and verification

Angular and geometric assemblies:

- Polygon-based grids: Grids matching geometric component shapes

- Assembly angle verification: Grid systems for accurate angular relationships

- Faceted surface representation: Grid accommodation of complex surface angles

- Geometric progression: Systematic approaches to complex geometric forms

- Precision angle construction: Grid-based accurate angle measurement and construction

Systematic Technical Drawing Process

Phase 1: Technical Analysis and Planning

Mechanical understanding and documentation:

- Function analysis: Understanding how mechanical components operate

- Assembly logic: Comprehending component relationships and interdependencies

- Material identification: Recognizing different materials and their visual characteristics

- Scale determination: Establishing appropriate drawing scale for detail requirements

- View selection: Choosing optimal viewpoints for technical communication

Reference preparation and grid planning:

- Technical drawing preparation: Gathering engineering drawings, photographs, and specifications

- Measurement verification: Confirming dimensional accuracy of reference materials

- Grid scale determination: Matching grid size to required detail level

- Critical dimension identification: Locating key measurements requiring accuracy

- Assembly sequence understanding: Comprehending how components fit together

Phase 2: Structural Framework Development

Primary component placement:

- Major assembly identification: Locating primary structural elements

- Spatial relationship establishment: Positioning major components accurately

- Proportional verification: Checking overall dimensional relationships

- Assembly axis determination: Establishing primary mechanical axes

- Component envelope definition: Outlining space occupied by each major component

Secondary component integration:

- Connecting element placement: Adding fasteners, linkages, and connecting components

- Detail component positioning: Locating smaller mechanical elements accurately

- Interface accuracy: Ensuring proper component interface relationships

- Clearance verification: Checking appropriate spacing between moving parts

- Assembly logic confirmation: Verifying realistic mechanical relationships

Phase 3: Detail Development and Technical Refinement

Component detail development:

- Surface feature indication: Adding machined surfaces, cast details, formed features

- Connection detail: Precise representation of mechanical fasteners and joints

- Material characteristic indication: Appropriate representation of different materials

- Functional detail emphasis: Highlighting critical operational features

- Manufacturing indication: Showing manufacturing processes and resulting surface qualities

Technical accuracy verification and enhancement:

- Dimensional checking: Verifying all proportional relationships against references

- Engineering logic verification: Ensuring mechanical feasibility of represented assemblies

- Technical standard compliance: Meeting industry drawing standards and conventions

- Component accessibility: Ensuring assembly and maintenance access representation

- Functional clarity: Clear communication of mechanical operation and relationships

Advanced Techniques for Complex Assemblies

Multi-View Coordination and Grid Integration

Coordinated view systems:

- Plan and elevation coordination: Multiple views sharing grid reference systems

- Section view integration: Cutaway views coordinated with external views

- Detail view coordination: Enlarged details maintaining grid relationships

- Assembly view hierarchy: Primary assembly views with supporting detail views

- Dimensional consistency: Coordinated measurements across multiple views

Exploded and cutaway representations:

- Component separation logic: Systematic disassembly sequences for exploded views

- Internal structure revelation: Strategic cutaway techniques for internal component access

- Assembly path indication: Clear representation of component assembly sequences

- Interface detail emphasis: Highlighting critical component connection details

- Functional relationship clarity: Maintaining component relationship understanding

Material and Surface Representation

Material indication techniques:

- Metal surface representation: Appropriate techniques for different metal finishes

- Plastic and composite indication: Suitable approaches for non-metallic materials

- Machined surface quality: Indicating different levels of surface finish

- Cast and forged surface indication: Representing different manufacturing processes

- Wear and damage representation: Showing operational wear and component aging

Surface texture and finish representation:

- Machining mark indication: Representing tool marks and surface patterns

- Polished surface techniques: Appropriate methods for reflective surface representation

- Textured surface approaches: Techniques for cast, forged, and formed surface textures

- Corrosion and wear indication: Methods for showing environmental effects

- Surface coating representation: Indicating painted, plated, and treated surfaces

Professional Applications and Industry Standards

Technical Illustration and Communication

Engineering documentation support:

- Patent illustration: Legal-quality technical drawing for patent applications

- Instruction manual illustration: Clear technical communication for assembly and operation

- Training material development: Educational illustration for technical training

- Maintenance documentation: Service manual illustration and component identification

- Marketing support: Technical illustration for sales and promotional materials

Manufacturing and design support:

- Concept development illustration: Early design stage visual communication

- Manufacturing process illustration: Production sequence and assembly documentation

- Quality control reference: Standard reference for inspection and verification

- Troubleshooting guides: Visual aids for problem diagnosis and resolution

- Component identification: Parts catalogs and inventory documentation

Digital Integration and Contemporary Methods

CAD integration and hybrid approaches:

- CAD reference usage: Technical drawing from computer-aided design references

- Hand drawing enhancement: Combining digital precision with traditional drawing expression

- Measurement verification: Using CAD models for dimensional accuracy checking

- Digital grid generation: Computer-generated grids for complex perspective requirements

- Hybrid workflow development: Combining digital planning with traditional execution

Professional software applications:

- Technical illustration software: Specialized programs for mechanical drawing

- CAD drawing export: Converting engineering drawings for illustration reference

- Grid generation tools: Software for creating specialized grid systems

- Measurement tools: Digital tools for accurate proportional checking

- Documentation integration: Combining drawings with technical specifications

Problem-Solving for Complex Mechanical Subjects

Common Technical Drawing Challenges

Proportional accuracy in complex assemblies:

- Component scale relationships: Maintaining accurate size relationships between parts

- Perspective distortion management: Accurate representation despite viewing angle effects

- Assembly spacing accuracy: Proper clearances and interference checking

- Functional relationship clarity: Clear indication of mechanical operation and interaction

- Technical feasibility verification: Ensuring drawn assemblies are mechanically possible

Detail complexity management:

- Information hierarchy: Balancing detail level with drawing clarity and readability

- Critical detail emphasis: Highlighting important features without overwhelming composition

- Assembly sequence clarity: Clear indication of component assembly and disassembly

- Maintenance access representation: Showing service and repair accessibility

- Operational indication: Representing mechanical function and component movement

Professional Quality Control Methods

Accuracy verification techniques:

- Dimensional checking procedures: Systematic measurement verification against references

- Engineering review processes: Technical accuracy confirmation by engineering professionals

- Functional logic verification: Checking mechanical feasibility and operational logic

- Industry standard compliance: Meeting relevant technical drawing standards and conventions

- Documentation correlation: Ensuring drawing accuracy matches technical specifications

Professional refinement strategies:

- Technical consultation: Working with engineers and technical specialists for accuracy

- Reference material verification: Confirming accuracy of source materials and references

- Industry standard research: Understanding relevant technical drawing conventions

- Quality benchmarking: Comparing work against professional industry examples

- Continuous improvement: Ongoing skill development and technical knowledge expansion

Career Development and Professional Applications

Industry Applications and Specializations

Technical illustration career paths:

- Engineering documentation: Technical drawing for engineering and manufacturing companies

- Patent illustration: Specialized legal illustration for intellectual property documentation

- Instruction manual illustration: Technical communication for consumer and industrial products

- Scientific illustration: Technical drawing for research and educational applications

- Architectural rendering: Mechanical systems illustration for building and construction

Specialized mechanical drawing applications:

- Automotive illustration: Vehicle systems and component illustration

- Aerospace technical drawing: Aircraft and spacecraft systems illustration

- Industrial machinery: Manufacturing equipment and process illustration

- Medical device illustration: Specialized technical drawing for medical and dental equipment

- Consumer product illustration: Appliance and product technical documentation

Professional Skill Development

Technical knowledge requirements:

- Engineering principles: Understanding mechanical engineering concepts and terminology

- Manufacturing processes: Knowledge of production methods and their visual characteristics

- Materials science: Understanding material properties and their representation

- Technical standards: Familiarity with industry drawing standards and conventions

- Safety and regulatory requirements: Understanding compliance and safety documentation needs

Portfolio development for career advancement:

- Technical accuracy demonstration: Examples showing precision and engineering understanding

- Complexity management: Illustrations showing ability to handle complex mechanical assemblies

- Industry specialization: Focused work in specific mechanical or technical fields

- Professional presentation: Industry-standard format and quality demonstration

- Problem-solving documentation: Examples of challenging technical drawing solutions

Mastering Technical Excellence

Using the grid method to draw complex mechanical objects represents a sophisticated integration of technical knowledge, systematic methodology, and artistic skill. Through consistent application of grid techniques combined with mechanical understanding, artists develop both technical accuracy and the analytical abilities necessary for professional technical illustration.

The journey toward mechanical drawing mastery requires patience, systematic practice, and deep understanding of mechanical principles combined with effective grid-based measurement techniques. These methods provide reliable frameworks that enable artists to achieve consistent technical accuracy while developing the specialized knowledge necessary for professional technical communication.

Professional mechanical drawing skills enable artists to work confidently across various technical and industrial applications, from patent documentation to educational materials. Through dedicated study and systematic application of grid techniques, artists develop the sophisticated technical awareness and precision necessary for lifelong career success in technical illustration and engineering communication.

Mastering Mechanical Drawing with Grids

For further study, explore grid perspective guide.

Ready to Try the Grid Method?

Put these techniques into practice with our free grid generator tool—trusted by 170,000+ artists worldwide.

Create Your Grid Now →